- +91-22-2760 0926

- sales@rpproducts.org

- Mon to Sat : 9am to 6pm

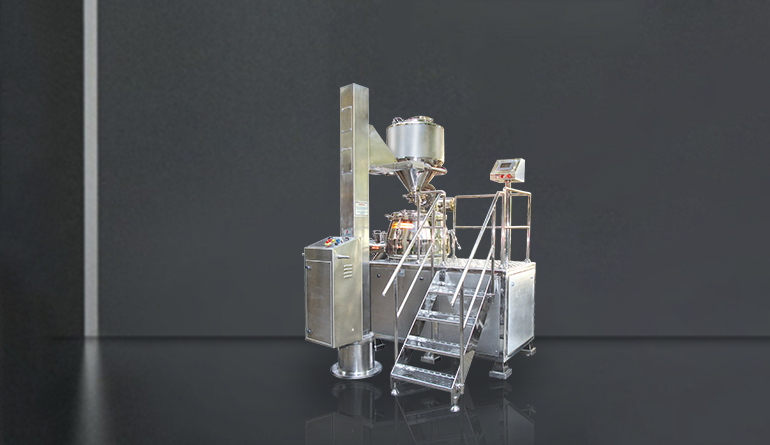

Rapid Mixer Granulator

- Home

- Rapid Mixer Granulator

Our Products

Specification

- For efficient dry and wet mixing of dry and wet granulation formulation processes.

- Programmable logic control for process parameter settings.

- Specially designed main blade and chopper for uniform mixing.

- Optional: WIP with accessories.

- Capacity: 50 to 1200 liters.

- Safety interlocks provided for operational safety.

Precision Granulation Solutions for the Pharmaceutical Industry

RP Products Pharma Equipments Pvt. Ltd. is a trusted manufacturer and supplier of Rapid Granulator Mixer, also known as Rapid Mixer Granulator (RMG Machine). Based in Mumbai, India, we deliver GMP-compliant granulation equipment engineered to provide fast, efficient, and homogeneous mixing and wet granulation for pharmaceutical, chemical, and nutraceutical industries.

Our Rapid Granulator Mixer ensures exceptional performance in Tablet Manufacturing, Capsule Formulation, and OSD (Oral Solid Dosage) production, making it an essential machine for modern pharma plants.

What is a Rapid Granulator Mixer?

A Rapid Granulator Mixer is a high-speed granulation equipment used to mix dry powders and convert them into uniform wet granules. These granules are then used in tablet compression and capsule filling.

The machine combines three major processes in one unit:

- Mixing

- Wet granulation

- Homogenization

Its superior speed, design, and efficient movement patterns produce consistent and high-quality granules required for pharmaceutical production.

Working Principle of Rapid Mixer Granulator (RMG Machine)

The RMG operates on a dual-action principle using a primary impeller and a high-speed chopper:

1. Impeller Action

The impeller rotates at a controlled speed, lifting, tumbling, and mixing the powder to create uniform distribution.

2. High-Speed Chopper

The chopper breaks down lumps formed during wetting and ensures uniform particle size.

3. Binder Addition

Liquid binder is sprayed onto the powder bed while the impeller mixes it to form wet mass.

4. Granulation Formation

Controlled shearing action transforms the wet mass into uniform granules.

5. Discharge

The granules are discharged through a pneumatically or manually operated valve.

This combination ensures high-speed granulation, reduced batch time, and consistent quality.

Key Features of Our Rapid Granulator Mixer

- Designed for dry & wet granulation

- GMP and cGMP compliant construction

- PLC-operated control panel for process automation

- Precision-designed impeller & chopper for uniform granulation

- Optional WIP (Wash In Place) system

- Capacity range: 50 to 1,200 liters

- Safety interlocks for operator protection

- High-speed granulation with batch time reduction up to 40%

Our RMG Machine is the ideal choice for manufacturers requiring speed, consistency, and reproducibility.

Applications of Rapid Granulator Mixer

Our Rapid Granulator Mixer plays an essential role across multiple industries:

Pharmaceutical Industry

- Tablet granulation

- Capsule filler granulation

- OSD formulations

- Moist granule preparation

Chemical Industry

- Mixing powders for catalysts, resins, and chemicals

Food & Nutraceuticals

- Granulation of health supplements, instant drink powders, etc.

Ayurvedic & Herbal Production

Wet mass preparation for herbal tablets and powders

Technical Specifications

| Parameter | Details |

| Model Range | 50L – 1200L |

| Construction Material | SS304 / SS316 |

| Impeller Speed | Adjustable |

| Chopper Speed | High-speed motor |

| Control Panel | Auto / Manual, PLC available |

| Heating System | Custom (if required) |

| Discharge Valve | Pneumatic / Manual |

| WIP System | Optional |

Why Choose RP Products for Rapid Granulator Mixer?

RP Products is recognized as one of the most reliable manufacturers of Rapid Mixer Granulators in Mumbai due to our commitment to engineering excellence and decades-long expertise.

35+ Years of Experience

Trusted by major Indian and global pharmaceutical manufacturers.

Customized Solutions

We design RMG machines tailored to your batch size and application.

GMP & cGMP Compliant

Meeting international quality and hygiene standards.

Advanced Manufacturing Facility

Precision fabrication and strict quality checks.

Strong After-Sales Support

Installation, training, servicing, and spare support available.

Consistent Performance & Durability

Built for long-term reliability under heavy-duty industrial use.

Our Network

We are a leading Manufacturer of Rapid Mixer Granulators in Agra | Ahmedabad | Ahmednagar | Ajmer | Amravati | Amritsar | Aurangabad | Bangalore | Beed | Belgaum | Bharuch | Bhavnagar | Bhopal | Bhubaneswar | Calicut | Chandigarh | Chandrapur | Chennai | Coimbatore | Cuttack | Daman | Delhi | Dhule | Ernakulam | Erode | Gangtok | Ghaziabad | Goa | Hubli | Hyderabad | Indore | Jaipur | Jalgaon | Jamshedpur | Jodhpur | Kolhapur | Kolkata | Lucknow | Ludhiana | Madurai | Mumbai | Mysore | Nagpur | Nashik | Navi Mumbai | Noida | Patna | Pondicherry | Pune | Raipur | Rajkot | Salem | Satara | Secunderabad | Shimla | Sikkim | Silvassa | Solapur | Srinagar | Surat | Thane | Udaipur | Vadodara | Valsad | Vellore | Vijayawada | Visakhapatnam

We are a leading Manufacturer of Jacketed Paste Kettle or Starch Paste Kettle in Agra | Ahmedabad | Ahmednagar | Ajmer | Amravati | Amritsar | Aurangabad | Bangalore | Beed | Belgaum | Bharuch | Bhavnagar | Bhopal | Bhubaneswar | Calicut | Chandigarh | Chandrapur | Chennai | Coimbatore | Cuttack | Daman | Delhi | Dhule | Ernakulam | Erode | Gangtok | Ghaziabad | Goa | Hubli | Hyderabad | Indore | Jaipur | Jalgaon | Jamshedpur | Jodhpur | Kolhapur | Kolkata | Lucknow | Ludhiana | Madurai | Mumbai | Mysore | Nagpur | Nashik | Navi Mumbai | Noida | Patna | Pondicherry | Pune | Raipur | Rajkot | Salem | Satara | Secunderabad | Shimla | Sikkim | Silvassa | Solapur | Srinagar | Surat | Thane | Udaipur | Vadodara | Valsad | Vellore | Vijayawada | Visakhapatnam

We are a leading Manufacturer of Conical Mill or Cone mill in Agra | Ahmedabad | Ahmednagar | Ajmer | Amravati | Amritsar | Aurangabad | Bangalore | Beed | Belgaum | Bharuch | Bhavnagar | Bhopal | Bhubaneswar | Calicut | Chandigarh | Chandrapur | Chennai | Coimbatore | Cuttack | Daman | Delhi | Dhule | Ernakulam | Erode | Gangtok | Ghaziabad | Goa | Hubli | Hyderabad | Indore | Jaipur | Jalgaon | Jamshedpur | Jodhpur | Kolhapur | Kolkata | Lucknow | Ludhiana | Madurai | Mumbai | Mysore | Nagpur | Nashik | Navi Mumbai | Noida | Patna | Pondicherry | Pune | Raipur | Rajkot | Salem | Satara | Secunderabad | Shimla | Sikkim | Silvassa | Solapur | Srinagar | Surat | Thane | Udaipur | Vadodara | Valsad | Vellore | Vijayawada | Visakhapatnam

We are a leading Manufacturer of Hydraulic Lifting & Positioning Device in Agra | Ahmedabad | Ahmednagar | Ajmer | Amravati | Amritsar | Aurangabad | Bangalore | Beed | Belgaum | Bharuch | Bhavnagar | Bhopal | Bhubaneswar | Calicut | Chandigarh | Chandrapur | Chennai | Coimbatore | Cuttack | Daman | Delhi | Dhule | Ernakulam | Erode | Gangtok | Ghaziabad | Goa | Hubli | Hyderabad | Indore | Jaipur | Jalgaon | Jamshedpur | Jodhpur | Kolhapur | Kolkata | Lucknow | Ludhiana | Madurai | Mumbai | Mysore | Nagpur | Nashik | Navi Mumbai | Noida | Patna | Pondicherry | Pune | Raipur | Rajkot | Salem | Satara | Secunderabad | Shimla | Sikkim | Silvassa | Solapur | Srinagar | Surat | Thane | Udaipur | Vadodara | Valsad | Vellore | Vijayawada | Visakhapatnam

We are a leading Manufacturer of Hydraulic Lifting & Tipping System in Agra | Ahmedabad | Ahmednagar | Ajmer | Amravati | Amritsar | Aurangabad | Bangalore | Beed | Belgaum | Bharuch | Bhavnagar | Bhopal | Bhubaneswar | Calicut | Chandigarh | Chandrapur | Chennai | Coimbatore | Cuttack | Daman | Delhi | Dhule | Ernakulam | Erode | Gangtok | Ghaziabad | Goa | Hubli | Hyderabad | Indore | Jaipur | Jalgaon | Jamshedpur | Jodhpur | Kolhapur | Kolkata | Lucknow | Ludhiana | Madurai | Mumbai | Mysore | Nagpur | Nashik | Navi Mumbai | Noida | Patna | Pondicherry | Pune | Raipur | Rajkot | Salem | Satara | Secunderabad | Shimla | Sikkim | Silvassa | Solapur | Srinagar | Surat | Thane | Udaipur | Vadodara | Valsad | Vellore | Vijayawada | Visakhapatnam

We are a leading Manufacturer of Pillar Type Bin Blenders in Agra | Ahmedabad | Ahmednagar | Ajmer | Amravati | Amritsar | Aurangabad | Bangalore | Beed | Belgaum | Bharuch | Bhavnagar | Bhopal | Bhubaneswar | Calicut | Chandigarh | Chandrapur | Chennai | Coimbatore | Cuttack | Daman | Delhi | Dhule | Ernakulam | Erode | Gangtok | Ghaziabad | Goa | Hubli | Hyderabad | Indore | Jaipur | Jalgaon | Jamshedpur | Jodhpur | Kolhapur | Kolkata | Lucknow | Ludhiana | Madurai | Mumbai | Mysore | Nagpur | Nashik | Navi Mumbai | Noida | Patna | Pondicherry | Pune | Raipur | Rajkot | Salem | Satara | Secunderabad | Shimla | Sikkim | Silvassa | Solapur | Srinagar | Surat | Thane | Udaipur | Vadodara | Valsad | Vellore | Vijayawada | Visakhapatnam

We are a leading Manufacturer of Square IPC’s (Insulated Panel Constructions) in Agra | Ahmedabad | Ahmednagar | Ajmer | Amravati | Amritsar | Aurangabad | Bangalore | Beed | Belgaum | Bharuch | Bhavnagar | Bhopal | Bhubaneswar | Calicut | Chandigarh | Chandrapur | Chennai | Coimbatore | Cuttack | Daman | Delhi | Dhule | Ernakulam | Erode | Gangtok | Ghaziabad | Goa | Hubli | Hyderabad | Indore | Jaipur | Jalgaon | Jamshedpur | Jodhpur | Kolhapur | Kolkata | Lucknow | Ludhiana | Madurai | Mumbai | Mysore | Nagpur | Nashik | Navi Mumbai | Noida | Patna | Pondicherry | Pune | Raipur | Rajkot | Salem | Satara | Secunderabad | Shimla | Sikkim | Silvassa | Solapur | Srinagar | Surat | Thane | Udaipur | Vadodara | Valsad | Vellore | Vijayawada | Visakhapatnam

We are a leading Manufacturer of Round IPC’s (Insulated Panel Constructions) in Agra | Ahmedabad | Ahmednagar | Ajmer | Amravati | Amritsar | Aurangabad | Bangalore | Beed | Belgaum | Bharuch | Bhavnagar | Bhopal | Bhubaneswar | Calicut | Chandigarh | Chandrapur | Chennai | Coimbatore | Cuttack | Daman | Delhi | Dhule | Ernakulam | Erode | Gangtok | Ghaziabad | Goa | Hubli | Hyderabad | Indore | Jaipur | Jalgaon | Jamshedpur | Jodhpur | Kolhapur | Kolkata | Lucknow | Ludhiana | Madurai | Mumbai | Mysore | Nagpur | Nashik | Navi Mumbai | Noida | Patna | Pondicherry | Pune | Raipur | Rajkot | Salem | Satara | Secunderabad | Shimla | Sikkim | Silvassa | Solapur | Srinagar | Surat | Thane | Udaipur | Vadodara | Valsad | Vellore | Vijayawada | Visakhapatnam

We are a leading Manufacturer of Weigh Truck in Agra | Ahmedabad | Ahmednagar | Ajmer | Amravati | Amritsar | Aurangabad | Bangalore | Beed | Belgaum | Bharuch | Bhavnagar | Bhopal | Bhubaneswar | Calicut | Chandigarh | Chandrapur | Chennai | Coimbatore | Cuttack | Daman | Delhi | Dhule | Ernakulam | Erode | Gangtok | Ghaziabad | Goa | Hubli | Hyderabad | Indore | Jaipur | Jalgaon | Jamshedpur | Jodhpur | Kolhapur | Kolkata | Lucknow | Ludhiana | Madurai | Mumbai | Mysore | Nagpur | Nashik | Navi Mumbai | Noida | Patna | Pondicherry | Pune | Raipur | Rajkot | Salem | Satara | Secunderabad | Shimla | Sikkim | Silvassa | Solapur | Srinagar | Surat | Thane | Udaipur | Vadodara | Valsad | Vellore | Vijayawada | Visakhapatnam

We are a leading Manufacturer of In Line Hi Efficiency Sifter in Agra | Ahmedabad | Ahmednagar | Ajmer | Amravati | Amritsar | Aurangabad | Bangalore | Beed | Belgaum | Bharuch | Bhavnagar | Bhopal | Bhubaneswar | Calicut | Chandigarh | Chandrapur | Chennai | Coimbatore | Cuttack | Daman | Delhi | Dhule | Ernakulam | Erode | Gangtok | Ghaziabad | Goa | Hubli | Hyderabad | Indore | Jaipur | Jalgaon | Jamshedpur | Jodhpur | Kolhapur | Kolkata | Lucknow | Ludhiana | Madurai | Mumbai | Mysore | Nagpur | Nashik | Navi Mumbai | Noida | Patna | Pondicherry | Pune | Raipur | Rajkot | Salem | Satara | Secunderabad | Shimla | Sikkim | Silvassa | Solapur | Srinagar | Surat | Thane | Udaipur | Vadodara | Valsad | Vellore | Vijayawada | Visakhapatnam